BLOG

POPULAR ARTICLES

From Waste to Worth: Surprising Benefits of PET Bottle Recycling

05 August, 2025

The proliferation of plastic packaging waste has defined consumption habits around the world. One of the most commonly made used and disposed-of packaging is plastic bottled water After being emptied, the vast majority is thrown away or placed in landfills. But through recycling, they come back into the economy as fabric, road fill, and basic goods.

Water bottle recycling unlocks more than just cleaner spaces or reduced landfill volume. It contributes to a larger chain of activity, one that supports production, development, and innovation in surprising ways. What begins as post-consumer waste often returns to the economy in forms not easily predicted.

Here are five such outcomes, each reflecting how this material recovery shapes broader industrial potential.

Boosting the Textile Industry with New-Age Materials

Textile manufacturing has steadily moved towards alternatives that reduce the need for new raw materials. A widely adopted input in this shift is PET derived from used plastic bottles. Under meticulous collection and complex/advanced processing. The PET bottles are converted into fibres that can be used in textile purposes. The Indian textile industry consumes more than 90% of recycled PET (rPET) used in the country, thereby becoming one of the biggest consumers of the same.

Approximately 90% of the PET plastic bottle waste is collected from the Himalayas, and approximately 8-12% million tons of PET plastic bottle waste are collected from the ocean.

What results from the process of recycling is a rPET fibre that can satisfy diverse industrial needs. Instead of relying on new resources, manufacturers gain access to a material that performs reliably in both structure and finish. Its applications extend across sectors, appearing in garments, storage solutions, furnishings, and specialised gear.

The shift from discarded plastic to finished fabric highlights a quiet but effective transformation, where waste becomes the starting point for practical, high-utility goods. By repurposing what was once single-use, a pathway opens that links waste recovery to everyday utility. This connection continues to strengthen as more producers seek materials that meet both functional and environmental goals. Now, recycled PET makes up more than 85% of polyester fibre consumed in India's textile sector, an indication of the way producers are leading business expansion through sustainable procurement. The lines between synthetic design and recycled source continue to blur as this transformation goes deeper.

Driving Innovation in Road and Infrastructure Projects

Infrastructure has become another unexpected beneficiary of recycled plastic. In particular, road construction now incorporates treated plastic waste into surfacing materials. When properly incorporated, such materials enhance the durability and flexibility of completed roads. Generally, up to 8%–10% of bitumen can be replaced by processed plastic waste without affecting performance. P-Concrett fibres are also employed to increase the strength, durability, and overall performance of road surfaces, particularly in regions subjected to heat, moisture, and high traffic.

Modified asphalt containing plastic exhibits better performance under high temperatures and heavy loads. The addition reduces cracking and water absorption, leading to longer service life and fewer repairs. The resulting mix performs well in areas exposed to harsh temperatures or growing traffic demands, offering greater stability and reduced wear over time.

Though the original form of the material has changed, its contribution to construction reflects how plastic bottle recycling supports infrastructure in ways that go beyond traditional expectations. This method also provides a scalable approach to handling large volumes of plastic waste, positioning it as a practical asset in public development planning.

Supporting a Localised Circular Economy

The recycle of plastic creates value at multiple levels. this value chain creates support for economic growth opportunities. Each stage generates jobs and local revenue. What used to wind up in rubbish bins or landfills is today seen from the perspective of utility. Recycled plastic is a material input that fuels processes in industries, further establishing its function as an agent for environmental as well as economic development.

Bottle recycling facilities are hardly autonomous operations. They connect with a wide chain of activities like transporting collected materials, sorting and high tech processing them, then supplying industries that rely on consistent, cost-effective input to keep production moving. Pashupati Group invests in this cycle, helping build industrial capacity while reducing environmental pressure. This kind of plastic recycle operation contributes directly to decentralised economic development.

Recycling plants often become anchors for auxiliary services. Small businesses that offer transportation, equipment maintenance, packaging, or reprocessing thrive around these facilities. The model keeps capital moving within communities and builds skillsets for technical and operational work. It provides support to both the formal and informal industries, generating a more robust industrial platform in areas where other industries are scarce.

Enhancing Agricultural Productivity Through Smart Applications

Agricultural practices have steadily absorbed recycled materials into everyday tools and systems. Among the most useful inputs are those formed from repurposed plastic bottles, now transformed into items built to last under open-sky conditions. Greenhouse sheets, irrigation pipes, seedling trays, and mulching layers are among the many solutions being shaped from recycled plastic.

They have advantages that extend beyond up-front cost. Long lifespan, low maintenance, and high resistance to outdoor environments make recycled plastic products a worthwhile option throughout agricultural operations. Conventional materials under heat, rain, or mechanical strain are prone to early wear-out. Recycled alternatives, in contrast, retain their shape and function across repeated use. For farms working within limited budgets or seasonal constraints, this reliability often leads to better planning and fewer interruptions.

Items such as compost bins, planter trays, fencing elements, and storage crates made from recycled inputs now appear across various agricultural environments. These components do not corrode, split, or decay easily, which reduces replacement cycles and stretches available funds. Over time, their presence supports more stable growing systems by lowering operational strain. Incorporating recycled inputs into common farming equipment offers more than just durability. It consolidates the pillars of food systems by advocating for long-term effectiveness, especially where reliable access to fresh materials could be constrained.

Reducing Overall Carbon Emissions Across Industries

Plastic bottle recycling consumes less energy compared to manufacturing new material from raw material. Reduced emissions during production minimize overall carbon emissions in industry.

Recycled plastic also helps streamline transport. Its lighter weight means shipments consume less fuel, leading to efficiency gains along distribution networks. These small savings grow quickly across high-volume operations.

PET recovered via bottle recycling is currently popularly utilized in packaging. It provides both structural support and design versatility, thus being fit for daily consumption. As regulations move toward environmental packaging, this procedure has become fundamental in fulfilling ecological objectives.

A Future Built on Repurposed Resources

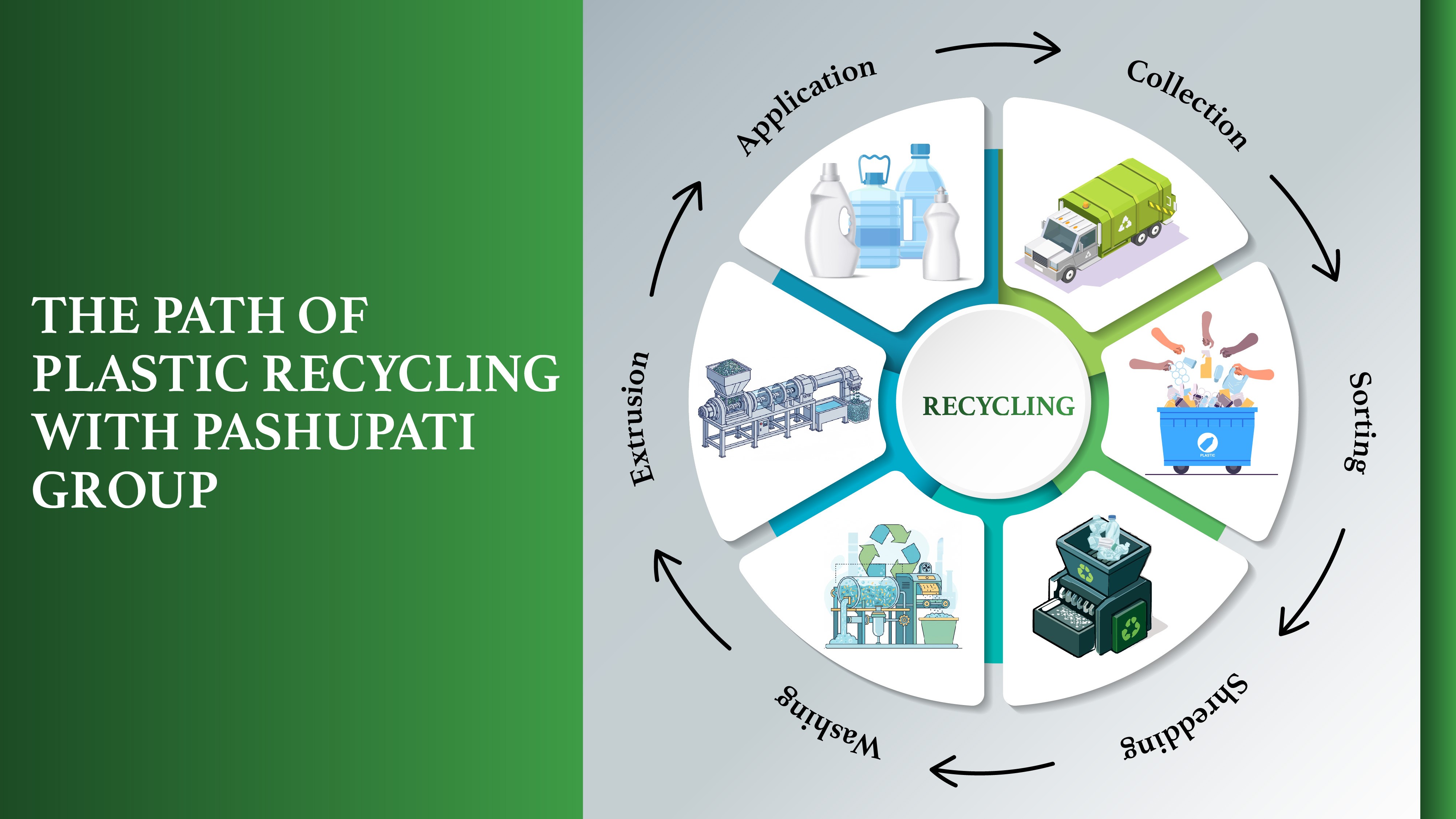

Recycled plastic does not simply vanish from sight. It follows a deliberate journey through facilities designed to extract value. Collection, cleaning, conversion, and shaping all serve as key phases in this cycle. The result is not just an object returned to use, but a resource repositioned within an industrial network.

Pashupati, with its plastic bottle recycling plant, carries this purpose forward at scale. Within its operations lies the ability to reduce waste, create products, support jobs, and reinforce supply chains. Pashupati Group has embraced this function not only to manage waste but to ensure that recycled materials become part of something productive and lasting.

The role of water bottle recycling continues to evolve. No longer a passive act of disposal, it now stands as a step toward regenerative industry. These efforts deliver gains that are measurable in output, cost, and environmental performance. Each recovered bottle signals a choice made for renewal over waste.

RECENT BLOGS