BLOG

POPULAR ARTICLES

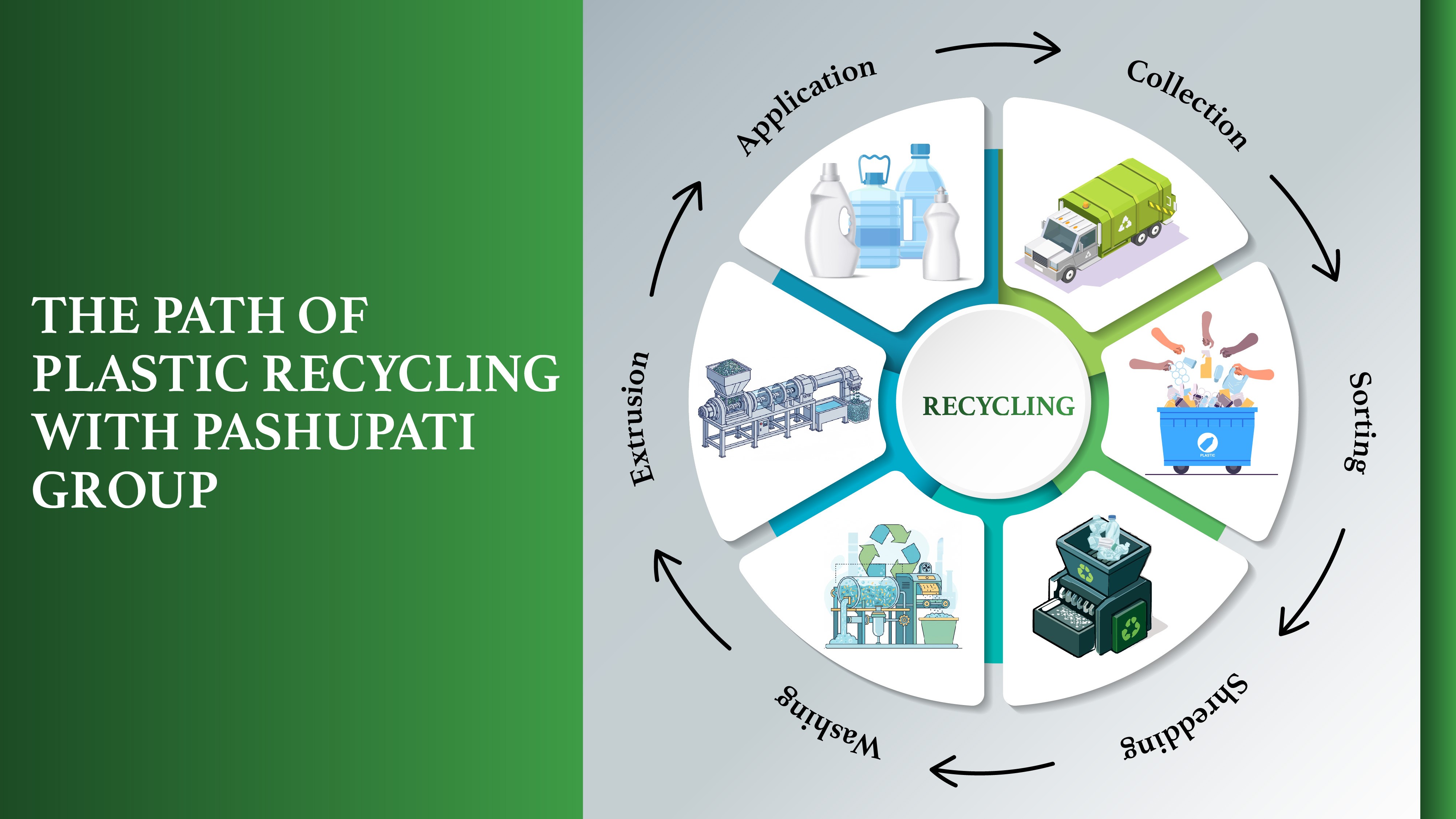

The Path of Plastic Recycling with Pashupati Group

14 November, 2025

Plastic waste carries real, recoverable value. A clear, disciplined pathway turns used bottles into dependable raw material for new products. Inside a modern plastic recycling plant, each stage tightens control and raises quality. Pashupati Group applies this method at scale, supplying recycling products to converters across the plastic recycling industry in India.

Intake, Baling and First Checks

Collection draws material from municipal networks, recovery facilities and traders. Baling compacts loose bottles into dense, uniform units that load, transport and store with ease. On arrival, receiving and inspection teams weigh, grade and tag each bale. Moisture, visible residues, embedded metals and foreign items receive close attention. Early discipline supports downstream stability and protects final specifications linked to food-grade and non-food-grade outputs.

Stream Selection for End Use

Separation assigns the right route from the start. Bottles suited to stringent hygiene targets move to the food-grade stream. Remaining material moves to lines dedicated to textiles, bags, strapping and general packaging. Clear routing preserves purity for the highest value applications and keeps every line focused on its target performance window.

De-Labelling, Pre-Wash and Polymer Control

Processing strips labels, caps, rings, paper and foils. Pre-washing follows to lift loose dust and organics. Polymer sorting then sets the core resin. Negative polymers exit the flow. PET proceeds. Colour segregation places clear PET in one family and coloured PET in another, aligning each batch with suitable end uses. Manual sorting adds a human quality gate, catching anything that machines flag as borderline.

Size Reduction for Stable Handling

Cutting and grinding reduce bottles to clean, consistent flakes. Controlled geometry helps washers, dryers and extruders deliver repeatable results. Uniform size also supports steady bulk density and predictable material flow along the line.

Cold Wash, Hot Wash and Thorough Rinsing

Cold wash removes remaining fines. A hot wash at 80 to 90 degrees Celsius uses detergent and sodium hydroxide solution to lift label glue and stubborn films from the PET surface. Multiple rinses with fresh water, typically three to four cycles, clear any residual chemicals. The outcome is a bright, clean flake that accepts heat and filtration with confidence.

Drying, Light-Fraction Removal and Metal Screening

Dryers bring moisture to process-ready levels. Air systems draw out fine label particles that separate during drying. A non-ferrous metal detector then screens the stream, securing a final defence against aluminium fragments. A second polymer sorting pass can run here to reaffirm PET purity before quality checks.

Testing and Packing

Laboratories sample every lot. Moisture, colour values, density and contaminant thresholds confirm line health and batch fitness. Conforming material is packed with full traceability, ready for extrusion or direct sale as PET flakes when customers specify flake-grade inputs.

Extrusion for Pellets and Bottle-Grade Readiness

Material that advances to extrusion passes through a heat phase that strips surface moisture and bio matter. The melt stage sits at 280 degrees Celsius and above, followed by fine filtration that captures micro-impurities. Clean melt forms strands that cool and cut into pellets for textiles, bags, sheets and moulding. Bottle-grade routes include an additional controlled heat treatment that aligns with food-contact standards. That path yields pellets for food-grade packaging lines that expect clarity, strength and stable processing.

Performance Levels and Application Fit

Bottle-grade outputs reach up to 99 percent closeness to virgin plastic in clarity and behaviour, supporting direct use in beverage and food packaging. Batches that target other markets power fibre spinning, non-wovens, straps, films and rigid parts. Portfolio breadth gives designers and procurement teams reliable choices that match both performance and sustainability goals.

Capacity that Strengthens Circular Supply

PET throughput at Pashupati Group reaches close to 10 million bottles per day. Typical water bottle mass of about 20 grams supports this scale by enabling high unit counts per tonne. Such capacity anchors steady supply for brands and converters and reinforces leadership within the plastic recycling industry in India.

Process Discipline that Builds Trust

Every stage in the sequence raises confidence. Collection and baling create order. Inspection and sorting shape purity. Washing and rinsing clean deep into the surface. Drying, light-fraction control and metal detection secure the stream. Testing, extrusion, filtration and pelletising deliver specification-true outputs. The result is a consistent pipeline from gate to bag that keeps production plans on track at customer plants.

Value for Brands, Value for the Environment

Recycled PET replaces a meaningful share of virgin feedstock while supporting strong product performance. Brands secure dependable input for packaging and textiles. Communities benefit from organised recovery networks and reduced landfill burden. Each tonne of output represents a step toward a tighter, more efficient loop where plastic recycling converts waste into long-term industrial resource.

Why this Method Works

Clarity of resin, clarity of colour and clarity of documentation drive smooth manufacturing. Polymer fidelity ensures stable melt behaviour. Clean surfaces protect filters and die heads. Tight moisture control prevents voids and haze. Traceable lots reduce guesswork during approvals and audits. Together, these gains turn post-consumer PET into high-grade recycling products that keep lines running, orders moving and sustainability targets advancing.

Pashupati Group combines scale, strict process control and application-ready outputs to set a practical benchmark for a modern plastic recycling plant. The approach reflects a simple idea with powerful effect: precise steps, executed the same way every day, transform used plastic into reliable raw material for the next cycle of making.

RECENT BLOGS