BLOG

POPULAR ARTICLES

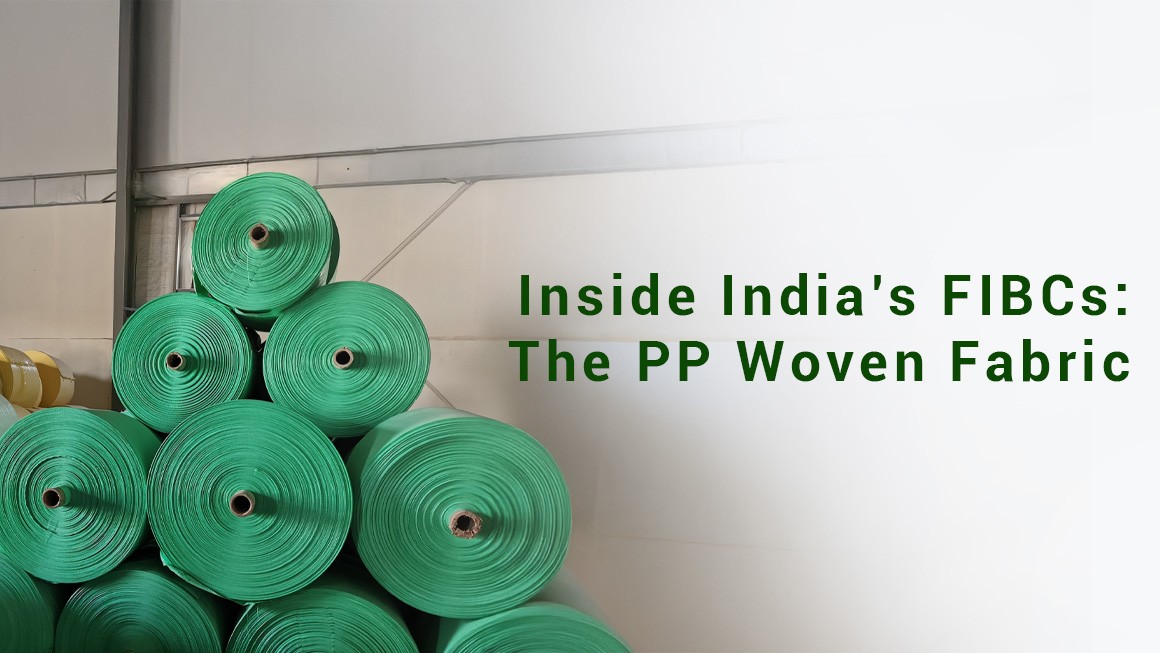

Inside India’s FIBCs: The PP Woven Fabric

10 October, 2025

Flexible intermediate bulk containers sit at the centre of Indian logistics for fertiliser, food, cement, polymers grain, minerals and chemicals. The fabric that makes them work comes from polyolefin tapes woven into strong, stack-stable cloth, then converted into U-panel, circular or baffle bodies with liners or coatings. India’s materials base supports this at scale. Domestic PP demand reached roughly 3.45 million tonnes in FY2023 with steady growth expected through FY2030, giving converters a reliable upstream for tape lines and looms.

Why Fabric Choices Matter in Indian FIBCs

Polypropylene dominates classic body cloth, yet PP brings stiffness, abrasion resistance and moisture control that help during filling, transit and open-yard storage. In practice, converters blend roles across body cloth, coatings and liners to meet product rheology, SWL targets and route conditions. Indian buyers lean on published benchmarks. The Bureau of Indian Standards maintains IS 14738 for FIBCs, consolidating earlier parts into the 2017 revision that covers materials, construction, type tests and marking for non-dangerous solids.

The Pashupati Manufacturing Stack

A strong FIBC programme begins with dependable fabric. Within India, Pashupati Laminators in Kashipur operates seven extrusion lines, about 320 circular looms and four lamination lines across a six-acre site, building a base capacity now stated at 35,000 tonnes per year for woven fabrics, bags and tarpaulin. Sister unit Salasar Techno Tex in Jaipur adds woven fabric capacity of 18,000 tonnes per year, widening geographic reach. At the bagging end, the group lists installed output of up to 3,000 tonnes per month across FIBCs, container bags and woven sacks, supported by in-house testing.

From Resin to Cloth: Indian GSMs That Carry The Load

Tape extrusion, orientation and weaving establish tensile strength and tear resistance, while GSM sets the tone for stacking performance and seam behaviour. Published product data on Pashupati’s packaging page shows PP fabric options from 36.5 to 250 GSM without lamination and HD fabric from 48 to 117 GSM without lamination, with laminated ranges reaching 93.5 and 138 GSM respectively. These spans allow designers to tune cloth for 500 to 2,000 kg SWLs with safety factors keyed to use class.

Standards, Testing and Indian Codes Buyers Actually Use

IS 14738 spells out cyclic top-lift, stacking and related evaluations, mirroring best practice for traceable marking and specimen counts. For small-pack supply chains that still need woven polyolefin strength, India retains specific BIS codes for sacks. IS 14887 covers woven sacks for 50 kg food grains and IS 14968 covers sugar sacks in 50 kg or 25 kg formats, including tape width, denier and stitch guidance used during acceptance tests across public distribution, sugar mills and agro processors. In tender language and factory QA, references to PP woven sacks come straight from these schedules.

What This Fabric Does Inside a Jumbo Bag

Body cloth takes most of the mechanical work, coatings limit sifting and weather pick-up, and liners deliver barrier control. Pashupati’s catalogue lists conductive bag options alongside circular, cross-corner and full-loop formats, signalling capability for static-managed handling when powders move through pneumatic systems or fast spouts. The same range publishes SWLs of 500 to 2,000 kg and safety factors of 5:1 or 6:1 with optional LDPE liners for moisture performance, aligning with what Indian buyers expect on audit trails.

Hygiene and Food-Contact Practice

Food and pharma routes demand cleanrooms, lint control and documented inspection. Pashupati’s food-grade FIBC notes include vacuum cleaning, pallet shrink wrapping, a 5 percent statistical check after palletising and a target defect rate of 0.01 percent, then individual inspection for pharma variants with metal detection and light-table review. Those measures support flour, sugar and starch movements where bag integrity and cleanliness drive losses or compliance.

India-Based Trade Signals That Back the Fabric Choice

Export data tracked by government-linked channels shows plastics holding ground and certain packaging sub-baskets advancing. IBEF reports FY25 year-to-January plastics exports at about US$10.34 billion with the category of FIBC, woven sacks, woven fabrics and tarpaulin up 17.2 percent on the comparable period, confirming demand for woven polyolefin packaging in overseas lanes. At a macro level this sits alongside domestic polymer supply growth, creating a favourable backdrop for fabric conversion and bag finishing inside India.

Where Pashupati Group Fits in The FIBC Bill of Materials

Designers specifying PP woven fabrics for body cloth or barrier layers gain access to a portfolio that spans PP and HD grades, liners and additives. The group’s packaging page details HD and PP fabric properties by GSM and type, while the FIBC page lays out construction choices from U-panel to baffle bodies with conductive variants for static-critical loads. That vertical setup helps align fabric GSM with loop geometry, coating weight and liner structure without long lead-time penalties between independent vendors.

Smaller Packs That Mirror Jumbo Performance

Procurement teams often harmonise specs across bulk and small-pack lines to simplify audits and supplier management. PP bags built from the same tape-line and loom infrastructure as jumbo cloth carry cement, fertiliser and sugar in 10 to 50 kg formats. BIS codes cited above govern these sacks, which share GSM, mesh and lamination variables with FIBC conversion, reducing surprise shifts in print quality or stitch strength between SKUs.

Built for Indian Supply Chains

The picture that emerges is straightforward. Indian standards establish clear test methods and marking. Indian polymer capacity underwrites consistent tape quality. Indian export data shows rising demand for woven polyolefin packaging in global lanes. Inside that framework, Pashupati Group assembles a practical stack that runs from resin conversion to fabric to tested bags with food-grade and conductive options, and with declared capacities for both fabric and FIBC output. For buyers, that combination shortens the path from GSM selection to certified lifting performance, and from liner choice to moisture outcomes, with documentation aligned to BIS codes and international audits.

RECENT BLOGS