BLOG

POPULAR ARTICLES

HDPE Fabric: The Industrial Packaging Material That Works

05 August, 2025

Industrial environments subject packaging to demanding conditions on a regular basis. Heavy loads, rough treatment, weather extremes, and chemical contact test material durability constantly. HDPE fabric performs consistently when facing such diverse operational stresses.

What Makes HDPE Fabric Different

HDPE fabric is made from high-density polyethylene, whose tightly packed molecular structure gives it exceptional strength and durability. Its dense molecular structure provides high strength without excess weight. Extruded plastic strips of this material are made in woven fabrics that combines flexibility with durability.

Chemical attacks rarely damage this material. Performance stays consistent across temperature ranges. Wet conditions from rain, snow, or humidity create few issues. Sunlight exposure takes considerable time to degrade the fabric.

Demanding locations find HDPE fabric performs well. Busy warehouses, active loading docks, dusty construction sites, and exposed outdoor storage all test materials severely. This fabric handles such environments without failing.

Strength That Matters

Industrial packaging needs strength. HDPE fabric delivers this through its woven construction. Individual strands support each other, distributing stress across the entire surface. When one area faces pressure, surrounding areas share the load.

This strength appears in everyday use. Bags filled with cement don't split at the seams. Containers holding sharp metal parts resist punctures. Sacks of grain maintain their shape during stacking and transport.

The material's tear resistance prevents small damages from becoming major failures. A minor nick won't spread across the entire surface. These characteristic saves money by preventing product loss and reducing replacement frequency.

Weather Resistance for Outdoor Use

Many industrial operations involve outdoor storage and transport. HDPE fabric performs well in these conditions. Rain doesn't penetrate the material easily. Snow and ice don't cause brittleness. Hot sun doesn't make it crack or fade rapidly.

This weather resistance means packages can sit outside without immediate deterioration. Construction materials, agricultural products, and industrial supplies remain protected during temporary outdoor storage.

Damp conditions that would damage other materials don't affect HDPE fabric significantly. This resistance maintains package integrity and protects contents from contamination.

Cost Benefits That Add Up

HDPE fabric costs less than many alternatives whilst lasting longer. The initial purchase price remains competitive, but the real savings come from durability. Packages that don't need frequent replacement reduce ongoing costs.

Lightweight construction saves money during shipping. Transport costs depend partly on package weight, so lighter materials reduce expenses. HDPE fabric provides protection without adding unnecessary weight.

Reusability multiplies these savings. HDPE woven fabrics can handle multiple uses before replacement becomes necessary. Empty containers get refilled repeatedly, spreading the original cost across many uses.

Different Industries, Different Needs

Agriculture uses HDPE fabric for seed storage, fertiliser packaging, and grain containers. The material keeps moisture out whilst allowing easy handling. Its strength supports heavy loads of bulk materials.

Construction industries rely on HDPE fabric for cement, sand, and aggregate packaging. The material handles rough treatment on job sites. Sharp edges and abrasive surfaces don't damage it easily.

Chemical processing plants need packaging materials that stay neutral around reactive substances. HDPE fabric avoids chemical reactions with stored contents, keeping products pure. Hazardous materials find safe containment in this non-reactive material.

Food packaging demands materials that maintain strict hygiene standards. HDPE fabric meets these requirements through its resistant surface characteristics. Microorganisms struggle to find suitable conditions for growth on this material. Cross-contamination risks decrease because unwanted substances cannot easily penetrate the fabric barrier. Cleaning becomes straightforward, allowing food processors to maintain sanitary conditions throughout their operations.

Environmental Considerations

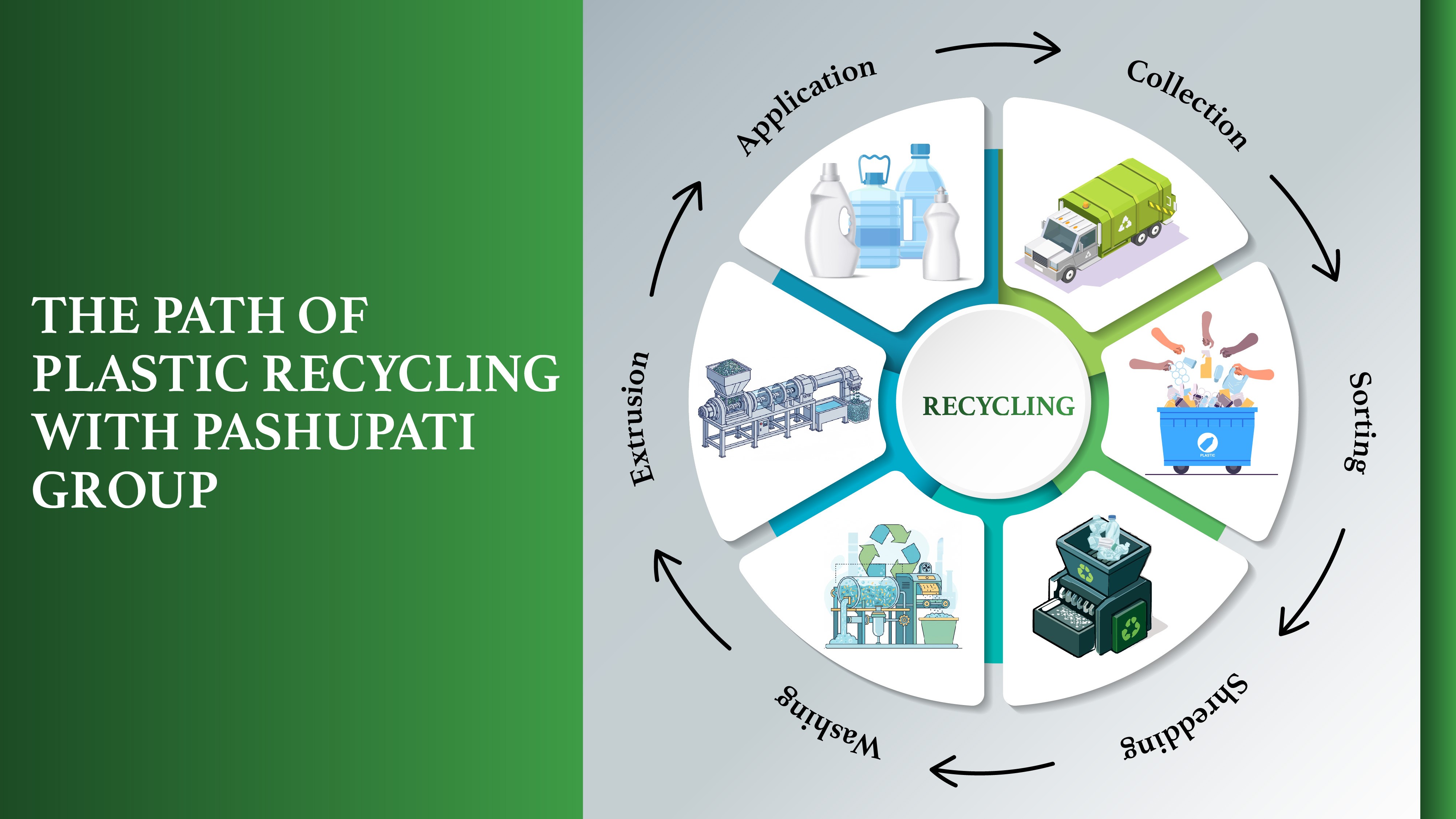

HDPE fabric recycling programs accept used materials for reprocessing. Old packages become new products, reducing waste. This cycle conserves resources and reduces environmental impact.

Manufacturing HDPE fabric produces fewer emissions than many alternatives. HDPE granules manufacturers use efficient processes that minimise energy consumption. The lightweight finished product reduces fuel use during transport.

The material's longevity means fewer replacements over time. Durable packaging reduces the total environmental impact by lasting longer and requiring less frequent manufacturing.

Practical Applications

HDPE bags serve countless industrial purposes. Small bags hold hardware and components. Large bags contain bulk materials. Custom sizes accommodate specific needs.

PP HDPE woven sacks combine different plastic types for enhanced properties. These hybrid materials offer improved strength or flexibility depending on formulation. Specific applications benefit from these tailored characteristics.

Bulk packaging applications showcase HDPE fabric's versatility. Jumbo bags hold tonnes of material whilst remaining manageable. Smaller containers provide precise portions for manufacturing processes.

Quality Standards and Reliability

Industrial packaging must meet strict requirements. HDPE fabric manufacturers test their products thoroughly. Tensile strength, chemical resistance, and environmental durability undergo regular verification.

Production quality control ensures consistent performance. Raw materials get inspected before use. Manufacturing processes follow established procedures. Finished products meet specified requirements.

These quality measures provide predictable performance. Businesses can rely on HDPE fabric behaving consistently across different batches and suppliers. This reliability supports efficient operations and reduces unexpected failures.

Customisation Options

HDPE fabric adapts to specific requirements. Thickness variations provide different strength levels. Weave patterns change flexibility and appearance. Additives enhance particular properties.

UV stabilisers extend outdoor life. Anti-static treatments prevent electrical buildup. Flame retardants reduce fire risk. These modifications expand the material's application range.

Colour options help with identification and sorting. Different colours distinguish between product types or handling requirements. This visual coding prevents mix-ups in busy industrial environments.

Supply Chain Advantages

HDPE fabric enjoys wide availability through established supply chains. Multiple suppliers ensure consistent access. Bulk purchasing reduces costs for high-volume users.

Standard sizes and specifications simplify ordering. Common dimensions fit existing equipment and processes. This standardisation reduces complexity and prevents compatibility issues.

Inventory management becomes easier with predictable supply and consistent quality. Businesses can plan purchases confidently and maintain appropriate stock levels.

Integration with Existing Operations

HDPE fabric works with current equipment and procedures. Existing filling machines, sealing equipment, and handling systems accommodate the material without modification. This compatibility reduces implementation costs.

Storage requirements remain minimal. HDPE fabric packages efficiently for inventory purposes. The material's stability means long-term storage doesn't cause deterioration.

Training requirements stay low because HDPE fabric handles similarly to other industrial packaging materials. Workers adapt quickly to its use and characteristics.

Real-World Performance

Daily industrial use proves HDPE fabric's effectiveness. Loading docks see constant package movement without excessive damage. Warehouse storage maintains product integrity over extended periods.

Transport conditions test packaging severely. Vibration, temperature changes, and handling stress don't compromise HDPE fabric performance. Packages arrive intact and functional.

Long-term storage applications demonstrate the material's stability. Products stored for months or years remain protected. The packaging maintains its protective properties throughout extended use.

Making the Right Choice

Pashupati Group understands how HDPE fabric serves modern industrial packaging needs. Strength, affordability, and dependability combine to create a material that works across many applications. Companies selecting HDPE fabric gain access to tested performance.

Years of industrial use have proven this material's capabilities. Manufacturing advances and recycling developments keep the material current with industry needs. Effective packaging choices balance immediate requirements with future performance expectations. HDPE fabric meets both criteria, offering dependable protection while enabling smooth operations and supporting environmental goals.

RECENT BLOGS