BLOG

POPULAR ARTICLES

The Process Behind the Polypropylene Bag: A Step-by-Step Look

30 July, 2025

Packaging used in industrial and commercial supply chains is regularly exposed to weight, abrasion, shifting temperatures and extended transit periods. In such conditions, the material itself must offer more than basic containment. Woven structures, particularly those made from polymers, have become a practical solution. Polypropylene fabrics stand out within this group due to their combined resistance, flexibility and load-handling capacity, making them well suited for continuous and demanding use.

The systems involved in producing such packaging are not improvised or incidental. They follow a carefully organised series of mechanical and thermal operations. Temperature control, equipment calibration, and material behaviour all interact at each stage. What begins as a neutral polymer transition through extrusion, weaving and conversion into a structure optimised for consistent, large-scale deployment.

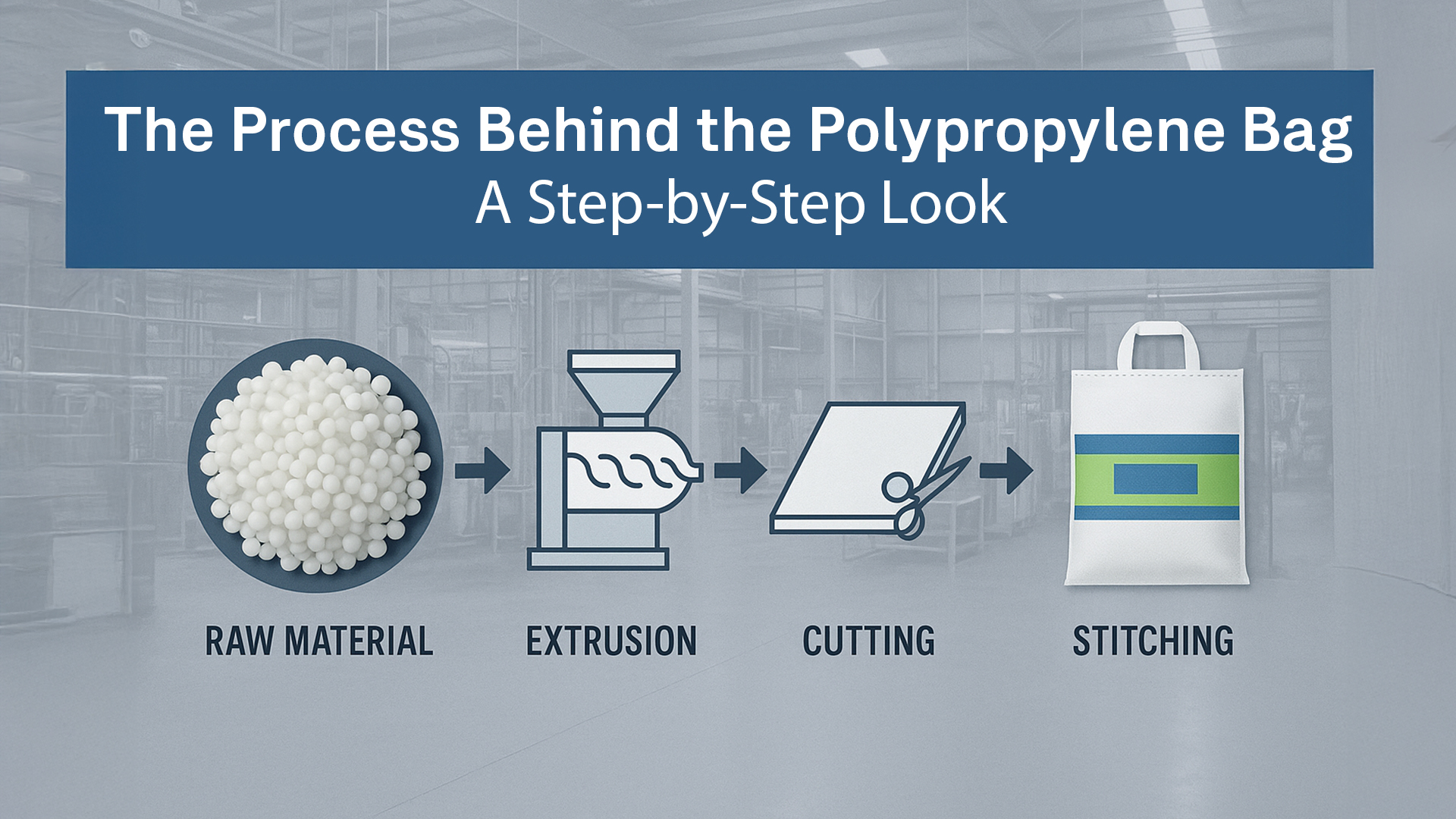

Raw Granules and Initial Transformation

Production begins with polypropylene resin. These are solid plastic granules, typically white in colour, chosen for their performance characteristics and suitability for woven applications.

The granules are then melted in an extruder, forming a continuous sheet of plastic. This sheet is rapidly cooled and sliced into thin tapes. These tapes form the structural base of woven polypropylene (PP) bags.

Stretching and Strengthening

The sliced tapes move into a controlled heating and stretching system. This part of the process aligns the molecular chains within each tape. As a result, the tensile strength improves without adding thickness or bulk. Finished tapes are collected on spools in preparation for weaving.

Forming the Woven Base

The spools are placed onto looms where weaving begins. Interlacing of the tapes takes place on high-speed circular or flat looms. The warp (vertical direction) and weft (horizontal direction) tapes are woven into a single piece of fabric. This forms the flexible but firm structure used for bags.

The density and weave type depend on the intended application. Some require tighter weaves for fine powders. Others demand looser weaves for breathability and reduced weight.

Coating and Lamination

Certain use cases require extra protection. In such instances, the woven fabric is coated with a layer of film to prevent moisture absorption or product leakage. This coating may be a thin layer of polypropylene or specialised barrier material.

Laminated versions often use BOPP film to allow sharp, high-resolution printing. In these cases, branding and design are directly integrated into the bag surface. These options are often chosen for retail visibility or export-grade packaging.

Cutting and Surface Printing

The coated or uncoated fabric is unrolled, then cut into measured lengths for conversion into bags. Cutting machines work in sync with printing systems where necessary. Logos, information panels and tracking marks are added using fast-drying, wear-resistant inks. Flexographic or rotogravure systems are commonly used to maintain clarity across production batches.

Bag Conversion and Stitching

The cut lengths are then stitched along the bottom edge using high-strength thread. Some bags remain open at the top, while others are shaped into tubular forms with sealed bottoms. Options such as drawstrings, valve tops or gussets may also be added at this stage.

Stitching machines are designed for volume as well as accuracy. Consistent alignment and reinforced seams ensure the bag can handle repeated lifting and transport without rupturing.

Inspection and Packing

Quality checks take place at various points, but the final stage involves inspection for printing clarity, fabric defects, size accuracy and stitch integrity. Any discrepancies are isolated, and the remainder are counted, bundled and packed for storage or delivery.

PP woven fabric manufacturers in India implement a mix of automated and manual inspection steps to maintain batch consistency.

Handling Waste and Recovery

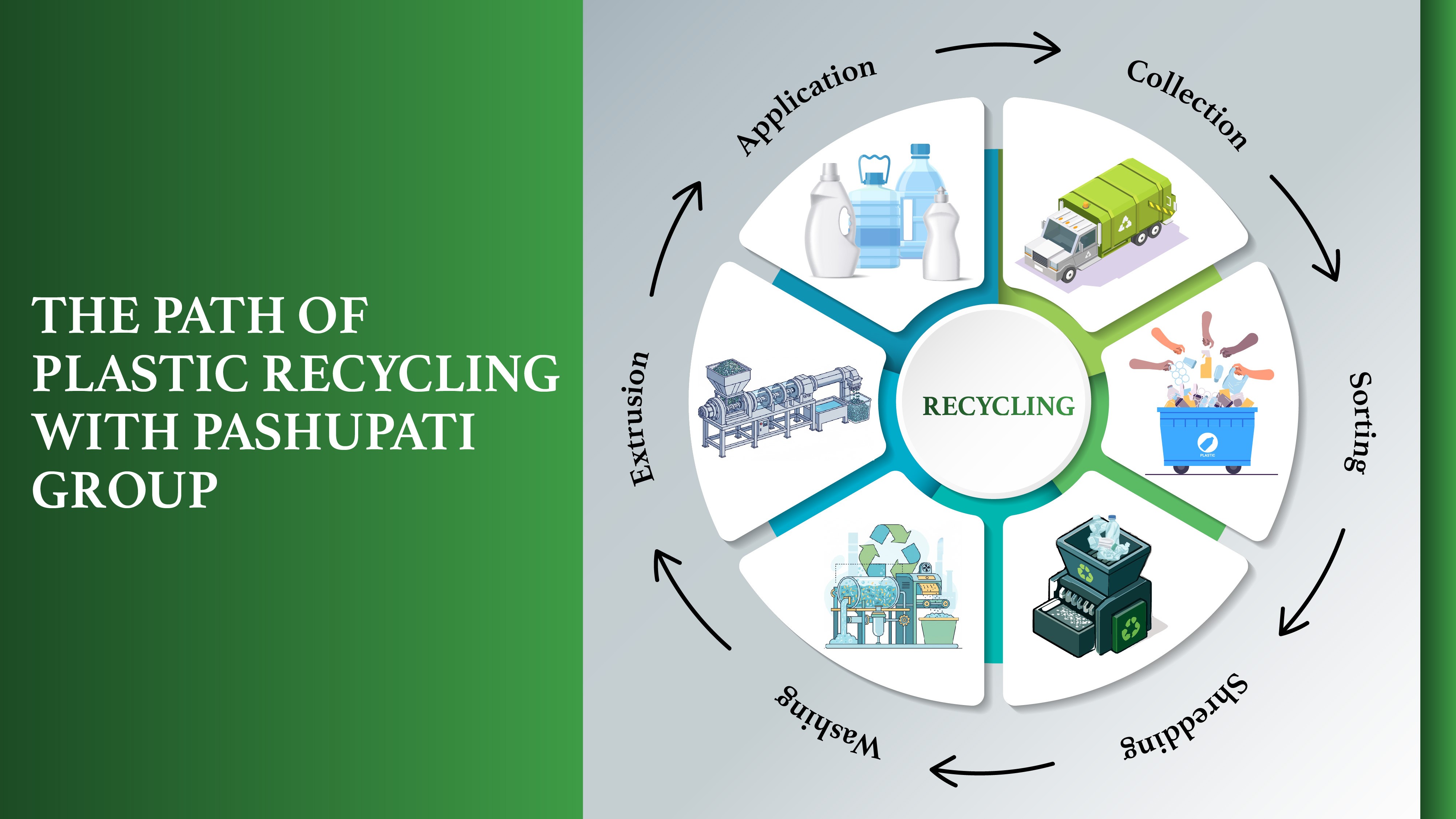

Scraps generated during trimming or printing are collected and often recycled in-house. Many facilities feed these scraps back into the extrusion stage after reprocessing.

A number of operations, including large producers like Pashupati Group, also maintain programmes for post-use recovery. This helps reduce environmental waste and supports a circular production model.

Why the Process Matters

Understanding the structured process behind polypropylene bags explains their continued relevance in modern packaging. From granular resin to strong, water-resistant sacks, every step in the chain contributes to reliability and performance.

The methodical conversion of polymer into fabric and finally into finished bags reflects both efficiency and attention to durability. By combining mechanical precision with scalable practices, manufacturers achieve volumes suitable for local markets and international distribution.

As a leading PP woven sack bag manufacturer, Pashupati remains part of a growing industry focused on improving product life, waste recovery and environmental stewardship.

Woven with Purpose

Every element within a polypropylene bag reflects the function it is meant to serve. Every part of the fabric serves a clear function, shaped by the demands of handling, storage and transport. Design choices are based on load requirements, environmental exposure and long-term use, rather than appearance or convention. It holds because it must. It endures because failure is not an option in high-volume operations.

The prevalence of woven polypropylene packaging bags can be understood through this lens. Materials are selected for performance. Methods are refined for consistency. The result is a format that continues to meet logistical expectations across industries where tolerance for error remains low.

RECENT BLOGS