Grade: HDBM01

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | Natural |

| Melt Flow Index at 2.16kg, 190° C | ASTM D 1238 | gm/10 min | 0.40 ± 0.10 |

| Melt Flow Index at 5kg, 190° C | ASTM D 1238 | gm/10 min | 2.0 ± 0.5 |

| Ash Content | ASTM D 5630 | % | <0.5 |

| Density at 23°C | ASTM D 792 | gm/cm3 | 0.95 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 27 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 90 ± 10 |

| Flexural Modulus | ASTM D 790 | Mpa | 1000 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 120 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 75 ± 5 |

| Vicat Softening Point | ASTM D 1525 | °C | 125 ± 5 |

| Bulk Density | Internal | Kg/m3 | 540 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | <0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, HDBM01 High Density Polyethylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly.

Product Application

HDBM01 Can be used for blown Film and blow molding applications such as container for lubricant, detergent etc.

Grade: HDBM02

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | White |

| Melt Flow Index at 2.16kg, 190° C | ASTM D 1238 | gm/10 min | 0.4 ± 0.1 |

| Melt Flow Index at 5kg, 190° C | ASTM D 1238 | gm/10 min | 2 ± 0.5 |

| Ash Content | ASTM D 5630 | % | < 3.00 |

| Density at 23°C | ASTM D 792 | gm/cm3 | 0.955 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 27 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 40 ± 10 |

| Flexural Modulus | ASTM D 790 | Mpa | 900 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 55 ± 5 |

| Hardness (Shore-D) | ASTM D 2240 | - | 80 ± 5 |

| Vicat Softening Point | ASTM D 1525 | °C | 125 ± 5 |

| Bulk Density | Internal | Kg/m3 | 550 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, HDBM02 High Density Polyethylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly.

Product Application

HDBM02 Can be used for blown film and blow molding applications such as container for lubricant, detergent etc.

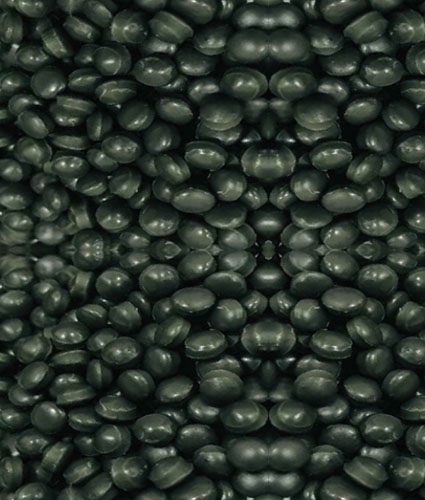

Grade: HDIM06

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | Green |

| Melt Flow Index at 2.16kg, 190° C | ASTM D 1238 | gm/10 min | 2.50 ± 0.50 |

| Melt Flow Index at 5kg, 190° C | ASTM D 1238 | gm/10 min | 10 ± 2 |

| Ash Content | ASTM D 5630 | % | < 0.9 |

| Density 23°C | ASTM D 792 | gm/cm3 | 0.945 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 25 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 30 ± 10 |

| Flexural Modulus | ASTM D 790 | Mpa | 700 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 40 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 75 ± 10 |

| Vicat Softening Point | ASTM D 1525 | °C | 125 ± 5 |

| Bulk Density | Internal | Kg/m3 | 540 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, HDIM06 High Density Polyethylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly.

Product Application

HDIM06 can be used for injection moulding applications such as crates, caps and closures etc.

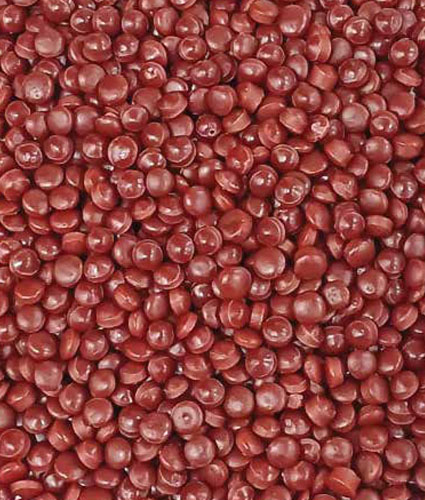

Grade: HDIM07

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | Red |

| Melt Flow Index at 2.16kg, 190° C | ASTM D 1238 | gm/10 min | 2.50 ± 0.50 |

| Melt Flow Index at 5kg, 190° C | ASTM D 1238 | gm/10 min | 10 ± 2 |

| Ash Content | ASTM D 5630 | % | < 0.7 |

| Density 23°C | ASTM D 792 | gm/cm3 | 0.945 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 25 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 30 ± 10 |

| Flexural Modulus | ASTM D 790 | Mpa | 700 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 50 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 75 ± 10 |

| Vicat Softening Point | ASTM D 1525 | °C | 125 ± 5 |

| Bulk Density | Internal | Kg/m3 | 540 plus/minus 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, HDIM07 High Density Polyethylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly

Product Application

HDIM07 can be used for injection moulding applications such as crates, caps and closures etc.

Grade: HDIM04

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | Blue |

| Melt Flow Index at 2.16kg, 190° C | ASTM D 1238 | gm/10 min | 2.50 ± 0.50 |

| Melt Flow Index at 5kg, 190° C | ASTM D 1238 | gm/10 min | 10 ± 2 |

| Ash Content | ASTM D 5630 | % | < 0.7 |

| Density 23°C | ASTM D 792 | gm/cm3 | 0.945 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 25 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 30 ± 10 |

| Flexural Modulus | ASTM D 790 | Mpa | 700 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 50 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 75 ± 10 |

| Vicat Softening Point | ASTM D 1525 | °C | 125 ± 5 |

| Bulk Density | Internal | Kg/m3 | 540 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, HDIM04 High Density Polyethylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly.

Product Application

HDIM04 can be used for injection moulding applications such as crates, caps and closures etc.

Grade: HDIM03

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | Dark Green / Grey |

| Melt Flow Index at 2.16kg, 190° C | - | - | 2.50 ± 0.50 |

| Melt Flow Index at 5kg, 190° C | ASTM D 1238 | gm/10 min | 10 ± 2 |

| Ash Content | ASTM D 5630 | % | <0.9 |

| Density at 23°C | ASTM D 792 | gm/cm3 | 0.945 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 25 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 30 ± 10 |

| Flexural Modulus | ASTM D 790 | Mpa | 700 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 40 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 75 ± 10 |

| Vicat Softening Point | ASTM D 1525 | °C | 125 ± 5 |

| Bulk Density | Internal | Kg/m3 | 540 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, HDIM03 High Density Polyethylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly.

Product Application

HDIM03 can be used for injection molding applications, such as Agriculture & Industrial Crates, Pellets, Helmets, Injection Molded Caps & Closures, Housewares, Baskets, Pails, Bucket etc.

Grade: PPIM01

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | Natural |

| Melt Flow Index at 2.16kg, 230° C | ASTM D 1238 | gm/10 min | 10 ± 2 |

| Ash Content | ASTM D 5630 | % | < 0.9 |

| Density 23°C | ASTM D 792 | gm/cm3 | 0.905 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 28 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 10 ± 5 |

| Flexural Modulus | ASTM D 790 | Mpa | 850 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 60 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 80 ± 5 |

| Vicat Softening Point | ASTM D 1525 | °C | 160 ± 5 |

| Bulk Density | Internal | Kg/m3 | 530 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, PPIM01 Polypropylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly.

Product Application

PPIM01 can be used for injection molding purpose such as Housewares, Consumer Products, Rigid Packaging, Furniture ect.

Grade: PPIM02

| Parameter | Test Method | Unit | Specification |

|---|---|---|---|

| Color | - | - | White |

| Melt Flow Index at 2.16kg, 230° C | ASTM D 1238 | gm/10 min | 15 ± 3 |

| Ash Content | ASTM D 5630 | % | < 2.5 |

| Density 23°C | ASTM D 792 | gm/cm3 | 0.91 ± 0.01 |

| Tensile Strength at Maximum Load | ASTM D 638 | Mpa | 22 ± 2 |

| Elongation at % Break | ASTM D 638 | % | 10 ± 5 |

| Flexural Modulus | ASTM D 790 | Mpa | 900 ± 100 |

| Notch Izod Impaact Strength | ASTM D 256 | J/m | 55 ± 10 |

| Hardness (Shore-D) | ASTM D 2240 | - | 80 ± 5 |

| Vicat Softening Point | ASTM D 1525 | °C | 155 ± 5 |

| Bulk Density | Internal | Kg/m3 | 530 ± 30 |

| Chips/gm | By weight | Nos. | 20-55 |

| Moisture Content | ASTM D 6980 | % | < 0.25 |

Product Features

This grade developed entirely from 100% post-consumer recycled plastic waste, PPIM02 Polypropylene provides multiple brands and producers a sustainable solution to meet their environmental commitments seamlessly

Product Application

PPIM02 can be used for injection molding purpose such as Housewares, Consumer Products, Rigid Packaging, Furniture ect.